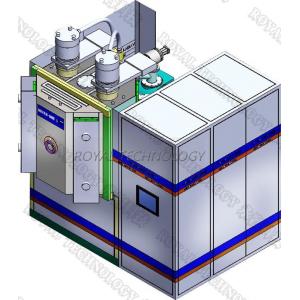

PVD Vacuum Coating Machine/Vacuum Metallizing Plant/PVD Coating Machine

Specifications

The PVD vacuum coating machine comes with all facilities, control systems and auxiliary appliances for the deposition of many metals on many substrates, such as plastic, metals, galss, ceramic, etc.

It’s equipped with the newest Ion Bombardment (plasma) option for preparation and pre-treatment of the part to be metalized: through the Ion Bombardment application it is possible to increase the adhesion onto the substrate of the metal deposited. Ion Bombardment process is applied directly in the same cycle of metalizing, before the metal deposition phase. The automation software and the systems guarantee maximum uniformity and quick operation.

The PVD vacuum coating machine can do decorative coating colors, such as gold, silver, brown, gray, black, rose gold, coffee, rainbow and blue, yogon ect.

Common industrial coatings applied by PVD are pure metal films like Cu, Al, Cr, Au, Ni, and compound films like TiN, TiC, TiCN, TiAlN, ZrN, CrN, CrSiN, ZrTiCN, TiAlCN, ZrC, TiALN, DLC, etc.

Technical configuration

- 1 (one) vacuum chamber (double shell, the middle layer for water-cooling) made by stainless steel, size can be custom-made

- 1 (one) spy porthole to check deposition

- 2 (two) removable stainless steel shield inside chamber

- 1 (one) electronic throttle valve in the pumping hole of chamber

- 1 (one) rigid base frame for the chamber

- 1 (one) multi-spindle satellite workpiece rotating system, which can be moved out of chamber integrally, stepless speed regulation, positive and negative rotating

- 1 (one) trolley for moving the workpiece rotating rack

- Mutli-electric arc targets (A100) and electric arc power

- 1 (one) Bias power

- 1 (one) Ion source as coating auxiliary device, 1 (one) set DC power (5000V/10KVA)

- 1 (one) Digital display compound vacuum gauge

- 1 (one) vacuum pump system including diffusion pump/molecular pump, roots pump, rotary vane pump, vacuum pipelines and valves, which can be automatic vacuum pumping.

- Mass flow controllers for Ar, 02, N2,C2H2

- 1 (one) heating system with U shape heating tubes, thermocouple, temperature controller, PID control

- Water separators for cooling

- 1 (one) Electronic control system including PLC control, color touch screen, alarm and protection system, control cabinets….make the automatic working cycle

Application:

- Watch & Clock industry (strap, case, dial, etc.)

- Hardware industry (sanitary ware, door handles, handles, locks, etc.)

- Construction industry (stainless steel plates, stair railing, columns, etc.)

- Precision industry (punch standard mould, forming mould, etc.)

- Tool industry (drill bits, hard alloy, milling cutters, broaches, tool bits)

- Automobile industry (pistons, piston rings, alloy wheels, etc.) as well as pens, glasses, etc., so that the surface is obtained with both beautiful and functional wear resistant layer. Main coated film layer are: gold ions, silver ions, titanium nitride film, titanium carbide film, a zirconium nitride film, a titanium aluminum alloy film, chromium nitride film, RP coated film and other super-hard functional metal film. The ion coated work piece after processing can improve the roles of hardness, wear resistance, corrosion resistance, and beautification.